|

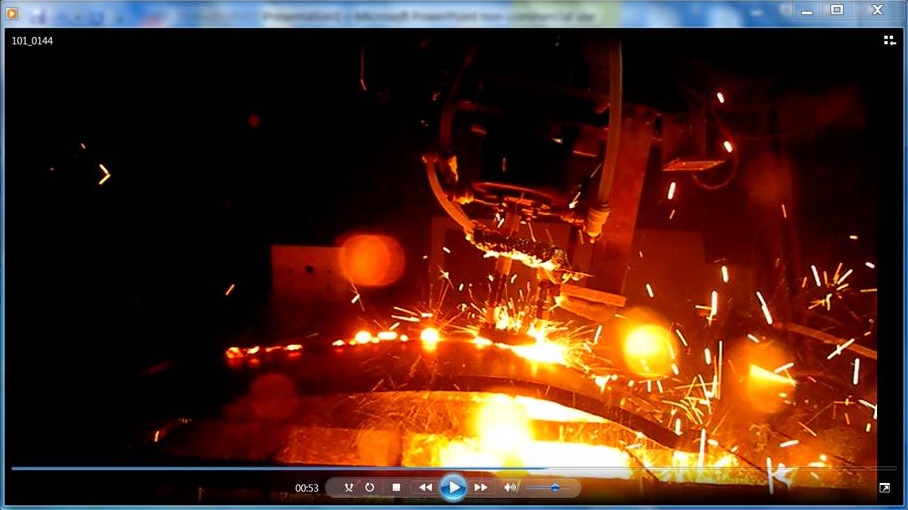

iiCut™ on a curved 1/2" steel plate cutting at 60 ipm with a 3/4" kerf (cut width).

|

iiCut™ |

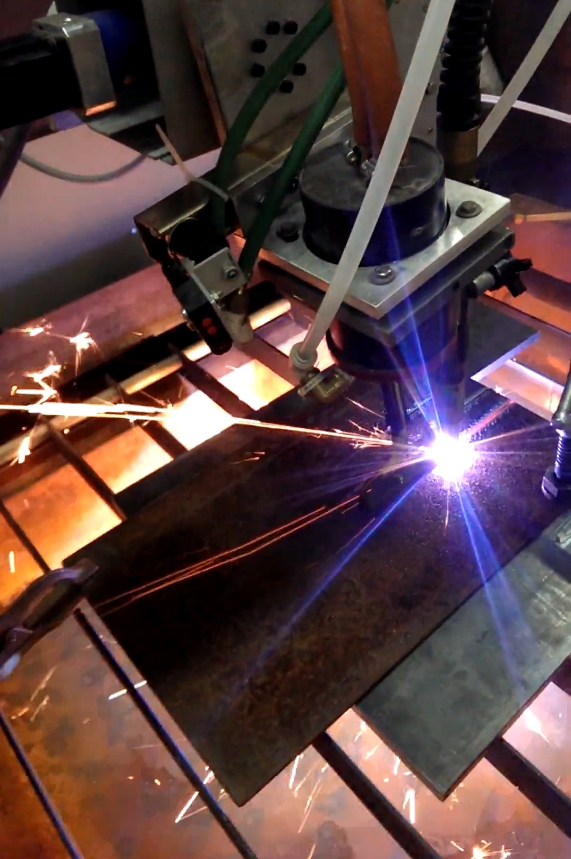

iiCut™ on 1/4" steel plate cutting at 160 IPM leaving a nice clean plasma-cut edge.

|

|

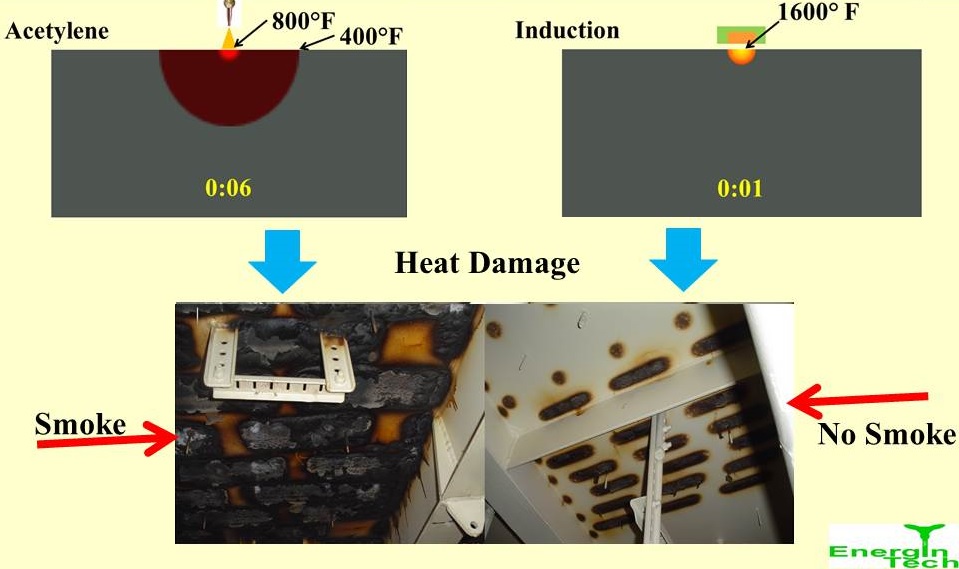

iiCut™ Reduces Damage To Surrounding Materials

Because induction is a much more intense, efficient heat source, heating up the plate to the critical temperature takes significantly less time, thus creating less heat dissappation into the surrounding plate. Therefore, less of the surrounding coatings/materials/etc. are damaged by the process, creating less fire hazard, less pollution and less re-work.

|

Our published processes include:

- iiWeld™: Hybrid Induction Arc Welding

- iiForm™: 3D Plate and Pipe Forming

- iiCut™: Induction Hybrid Cutting

- Laser Pipe and Thin Plate Forming